Reliable Equipment, Support, and Service. All under one roof.

Find Your Solution

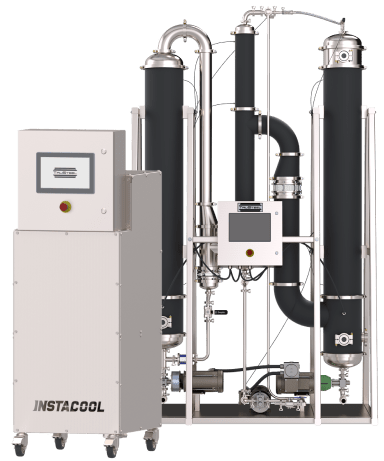

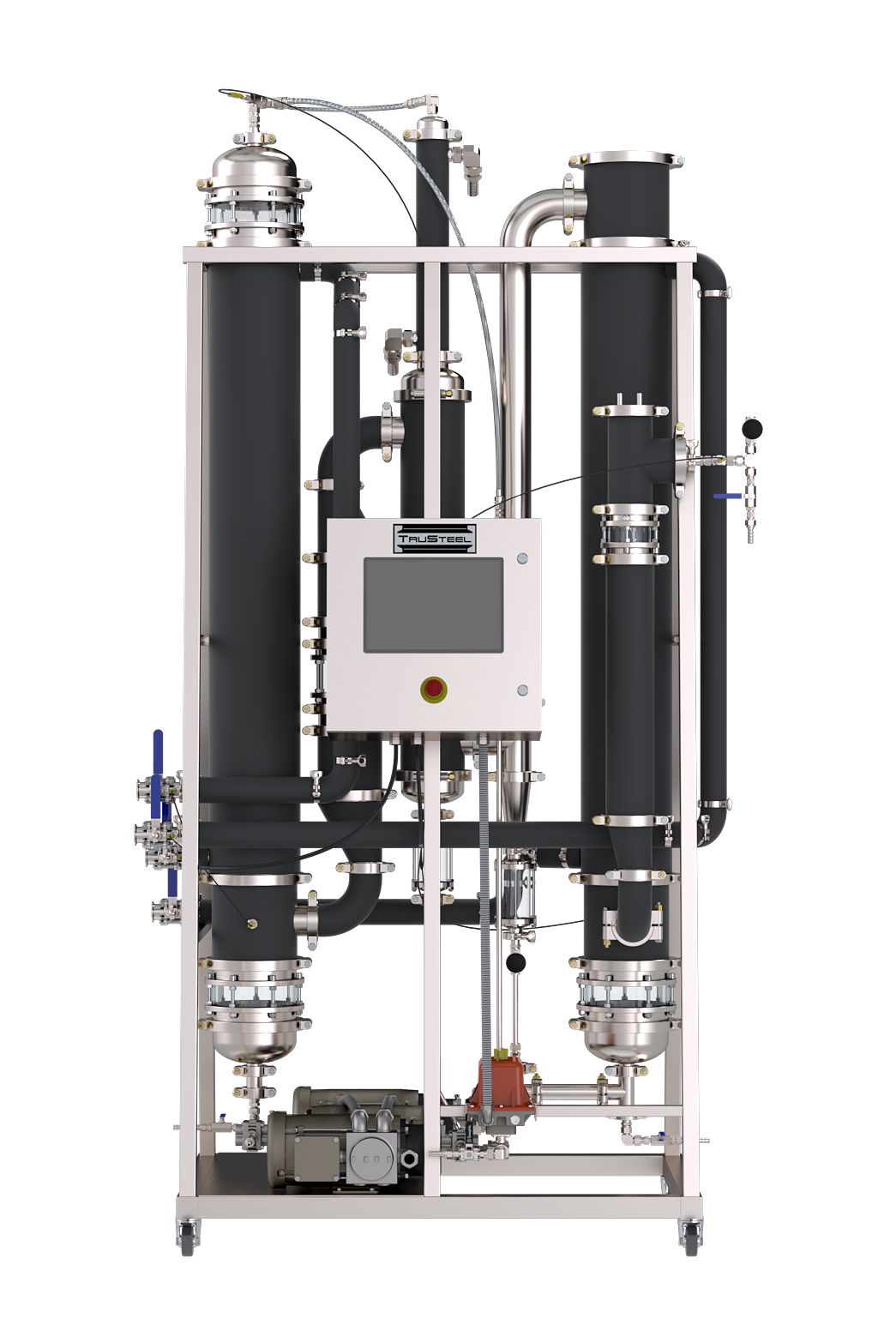

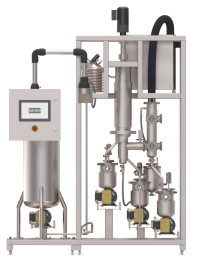

Clients working with TruSteel lean on our team of experts and in-house equipment solutions for solvent storage/transfer, solvent chilling, extraction, filtration, solvent recovery, reactors, and distillation systems for a continuous and fully automated process, eliminating bottlenecks and providing our clients a modular system that is simple to scale up.

looking for custom extraction equipment?

Our engineers can build the right solution for you.

Why Choose TruSteel?

State of the Art Solutions

State of the Art Solutions

Our solutions are tailor-made to the highest engineering standard for your specific application, your requirements, and your future. TruSteel technology can be found in pharmaceutical, nutraceutical, food/bev and agricultural applications, paving the way for the future of processing and manufacturing.

Return on Investment

Return on Investment

Combining high-efficiency solutions with high output capabilities and automation to reduce labor and increase consistency, our clients have some of the highest returns on investment in the industry and can grow by taking market share quickly!

TruSupport for Continuous Production

TruSupport for Continuous Production

TruSteel’s clients have the benefit of working with one company for all of their ethanol extraction and processing needs, including maintenance and service of the equipment, spare parts kits, and on-site training on all things extraction, which allows them to have a consistent product and an extremely high uptime in production, ultimately creating higher profit margin.

OEM & Knowledge Provider

OEM & Knowledge Provider

We have personal experience in the various industries that we work in and are a source of knowledge for our clients to find solutions to pressing problems quickly! We manufacture everything in the USA and keep engineering in-house so that we have the control to constantly improve on our equipment design and software.

Industries Served

With Pharmaceutical grade equipment, we are able to serve the needs of many industries.

Featured Customers

TruSteel Guarantee

TruSteel is a professional team of engineers with years of experience in the extraction industry. Our tagline “By Extractors, For Extractors” reflects our knowledge of the industry and our commitment to help it thrive on a large scale. TruSteel is based in the USA and all our products are built right here in California. We only source the highest quality parts for the most robust, long lasting machines on the market.

The production capacities of TruSteel’s Extraction Series set these machines apart from any other in the industry. But, more importantly, a professional customer service team backs our products to ensure you are 100% satisfied with all aspects of your investment.