InstaCool Series

InstaCool Solvent Cooling System

100-300 US Gal/hr (379-1135 Liters)

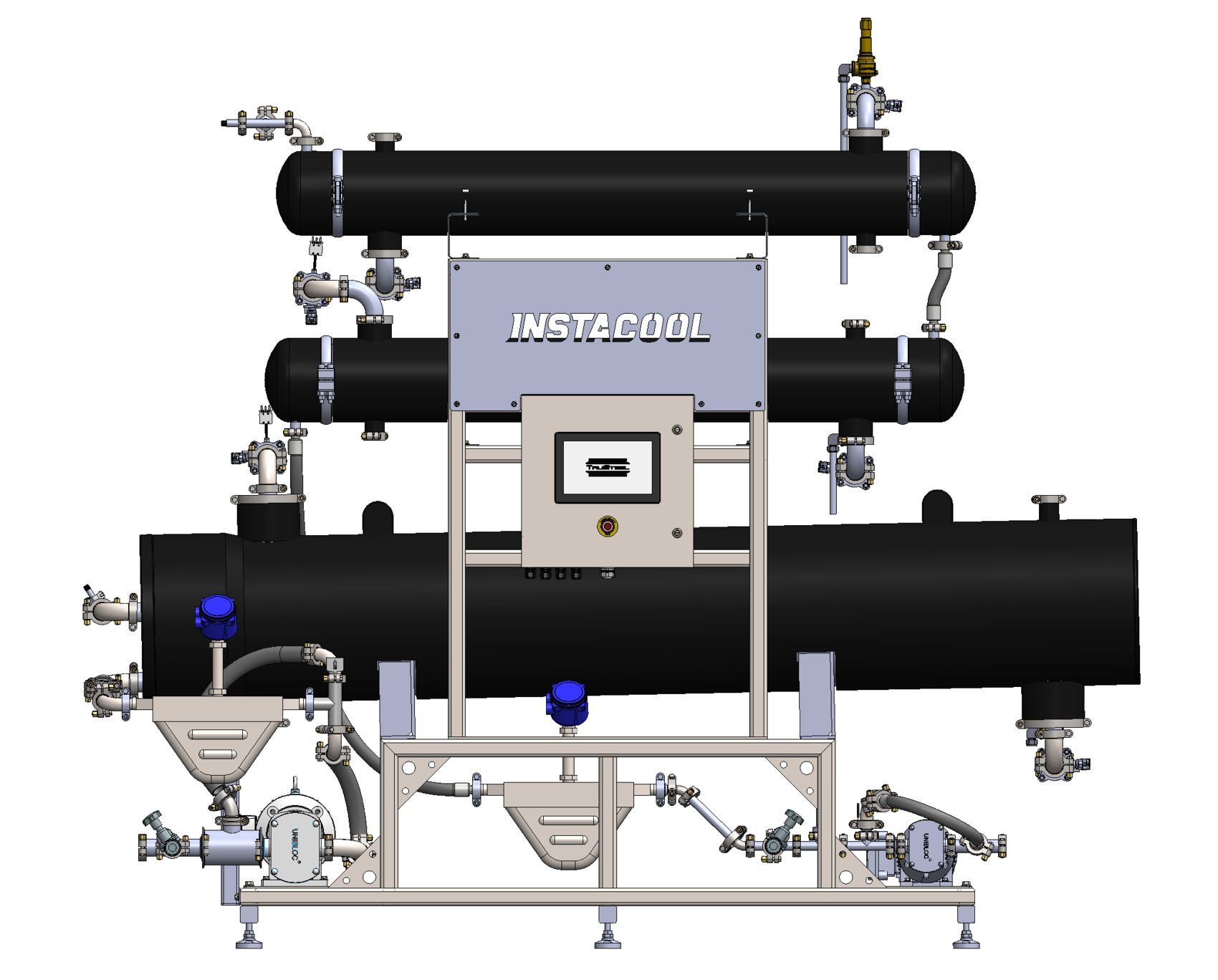

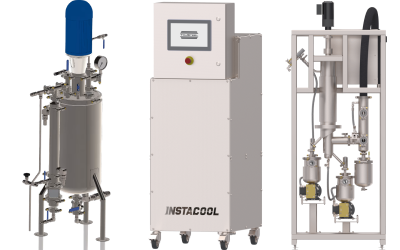

The InstaCool is designed to chill or heat up to 300 US Gal/hr of solvent, oils, or other liquids and generate precise amounts continuously or in batches for use in centrifugal extraction, reactions, or other processes. Pairs with heaters and chillers to achieve variable set points from room temperature down to -55C or up to 150C, completely inline. Pair upstream and downstream tanks with optional level sensors to ensure the pump never runs dry, and your discharge never over flows. Control precise dosing with adjustable volumes at the push of a button and monitor additional tank temperatures on the included additional inputs. Tanks are available upon request to configure the ideal solution for your processing facility. Features 7 precision temperature sensors for measuring process and heat transfer fluid temps. Automation comes standard with a C1D2 rated 12 inch HMI with maximum pixel density, built-in fail safes, configurable users and recipes, alarms, data logging, and remote access from anywhere in the world.

Fast, Efficient Solvent Cooling/Heating

A revolutionary way of controlling temperature and dosing solvents, chemicals, oils, etc. at precise rates and volumes, completely inline.

Options up to 300 US Gal/Hr

(1135 Liters) Per Hour of Solvent

Complete Automation

Modbus Integration Compatibility

-55°C – 80°C Rated

Dial in your Ideal Extraction Temp

Continuos Process Flow

Eliminates Solvent Pre-Chilling and Storage

C1D2 Compliant

Hazloc Motor & Intrinsically Safe HMI

Peer Engineer Reviewed

Streamlined Safety Approval Process

UL and cUL Compliant

Control Panel, PLC and Motors

Made in the USA

Highest Standard of Quality & Testing

Quality Standards

| Base Unit (Inside C1D2 Zone) Dimensions: | 41 x 26 x 61 (L x W x H inches) |

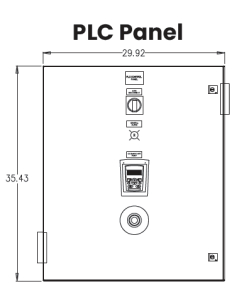

| PLC (Non-Hazardous Zone) Dimensions: | 12 x 30 x 36 (Approx. L x W x H inches) 208-230V 1Ø 30A |

| Chillers | Models vary to meet your temperature and flow rate requirements. Configurations from 30 to 300 US Gal/hr are available. |

- Wetted Materials: 304 & 316 Steel, PTFE

- Compatible with: Ethanol, Methanol, Heptane, Hexane, Acetone, Acetonitrile

- Peer Engineer Reviewed

- USA and Canadian UL Listed Panel & Motors

- Installation, Training & Support Included

- 1 Year Warranty

The instacool is a revolutionary temperature control unit for inline chilling of clean solvent. Processors can supply the extraction equipment with cold solvent when they need it, maximizing their extractors performance while preventing the need for pre-chilling and storing high volumes of solvent. It’s design also eliminates the risk of leaking refrigerant into the process.

The intelligent controls allow you to maximize the performance of any chiller unit on the market, and features modbus communication for easier networking.

As with all TruSteel products, the control module seamlessly integrates into your lab space. This allows for remote access, data-logging, and performance monitoring.

The InstaCool is an investment in your future as this scalable solution that can grow with your business. Processors using this system have the ability to easily add more extractors and provide more solvent without having to purchase another unit or use consumables like liquid nitrogen.