AUTOMATED SOLVENT RECOVERY SYSTEMS

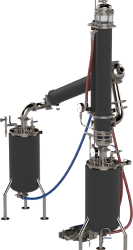

AUTOVAP™ 30 Solvent Recovery System

Up to 45 US Gal/Hr* (170 liters) per hour recovery

The AV30 adds full automation with our custom engineered AutoVap software package, as well as a more compact package over the AV15. It is the most efficient solvent recovery system when comparing throughput to footprint. 13 points of data measurement combined with built in fail safes, alarms, data logging, and remote access makes the AV30 stand alone as the industry leader with up to 99% recovery rate and up to 45 US Gal/hr.

The AutoVap 30 has a residence time of less than 3 minutes, is C1D2 Compliant, Peer Engineer Reviewed, uses 3-A sanitary components, as well as a UL 508B listed PLC.

Fast, Efficient Solvent Recovery

The AV30 is the most efficient solvent recovery system when comparing throughput to footprint.

With built in fail safes, alarms, data logging, and remote access, the AV30 stands alone as the leader in the industry.

*Different solvents may result in

varied recovery rates.

Up to 45 US Gal/Hr*

(170 Liters) Per Hour Recovery

Complete Automation

Easy to Read Display

95-99% Solvent Recovery

Precise Parameters/Control

Low Residence Time

Less than 3 Minutes

C1D2 Compliant

Hazloc Motors & Intrinsically Safe HMI

Peer Engineer Reviewed

Streamlined Safety Approval Process

UL 508B Compliant

US & Canada

Made in USA

Highest Standard of Quality & Testing

Quality Standards

| Chiller (12 Ton Cooling Power) | 230V/3Ø/65A or 460V/3Ø/43A 80.3 x 35 x 65.6 (LxWxH inches) 884 lbs. (empty weight) |

| Vacuum Pump | 110V/1Ø/3A 9 x 15 x 7 (LxWxH inches) 40.3 lbs. |

| Water Heater | Option 1: Electric 208V/3Ø/99.9A 240V/3Ø/79.4A 480V/3Ø/43.3A 10 x 24 x 15.75 (LxWxH inches) Option 2: Gas 120V/1Ø/12A; 300K BTU 1/2″ Gas Connection |

| Control Panel [PLC] | 208-240V / 1Ø / 27.5A DIM: 8 x 36 x 48 (LxWxH inches) |

| AV30 Footprint | 48 x 32 x 91 (LxWxH inches) Weight: 850 Lbs. |

- Up to 45 US Gal/Hr Recovery *

- 95-99% Removal 1st Pass

- <3 Minute Residence Time

- Fully Automated Operation

- Fail Safes, Alarms, Data Logging, Remote Control

- Material: Stainless Steel, PTFE, & Borosilicate

- Compatible with: Ethanol, Methanol, Heptane, Hexane, Acetone, Acetonitrile

- UL Listed Ancillary Equipment Included: Heating System, Cooling Systems, and Vacuum

- Solvent Resistant Touch Screen

- Engineer Reviewed for Safe Operation in Hazardous Locations

- USA and Canadian UL 508B Listed

- IQ/OQ Optional

- Installation, Training & Support Included

- 1 Year Warranty

*Different solvents may result in varied recovery rates.

| Facility Power | 480V | 240V | 208V |

| Phase | 3Ø | 3Ø | 3Ø |

| Total Amps (Electric Heater) | 118 | 176 | 196 |

| Total Amps (Gas Heater) | 87 | 109 | 109 |