Since 2017, TruSteel has been designing and manufacturing falling film evaporator systems (The AutoVap) in various sizes. Over the years, many different iterations of the design have been released. This guide is intended to help you understand the differences in the generations and inspect used AutoVaps for defects and incomplete packages.

AutoVap15

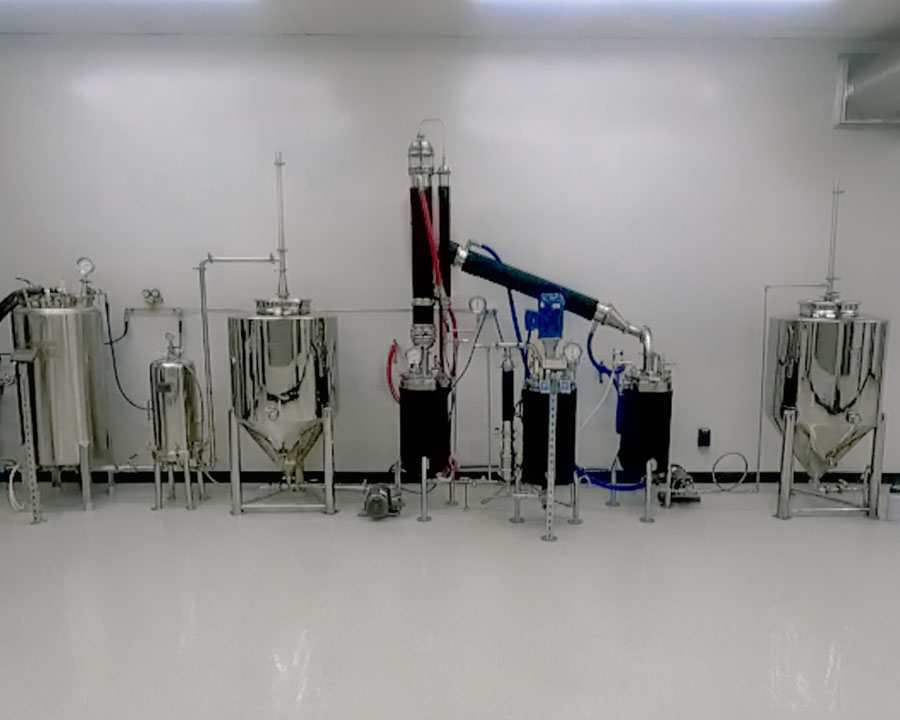

The AV15 was the first AutoVap released in September 2017. Currently there are four different generations and two different models of the AV15.

AV15 Basic: sold as a package with;

- 200K BTU gas or 18KW electric heater

- Plumbing manifolds for heater and chiller

- 5 ton chiller

- Diaphragm style vacuum pump

- Gear style feed pump and VFD (variable frequency drive) controller with a remote to turn the VFD on/off and adjust the speed.

AV15 Plus: intended to create a stepping stone into the AV30, the AV15 Plus has addtional features;

- 200K BTU gas or 36KW electric heater

- Plumbing manifold for heater and chiller

- 12 ton chiller

- Ethanol discharge pump to continuously remove recovered ethanol from the system for continuous production.

Generation 1: (Buyer score: 4/10)

Generation 1 can be identified by the connection between the evaporator and the residue vessel. Early generations utilized a 1.5 inch triclamp connection that is no longer recommended. This version also utilizes a ¾ tube diameter heat exchanger which limits the throughput to 15 gallons/hour. Threaded NPT fittings are used for the heat exchangers, unlike later generations which utilize the superior LOK style fittings, these have a smaller bore reducing circulation capacity. Additionally, Chemsteel/Oberdorfer brand pumps were used which are known to fail prematurely due to their materials of construction and helical gear design. Generation 1 often has preheaters that vary in size, from single tube to 4 inch diameter. Still better than a rotovap! But not the best option among other AutoVaps.

Key Points: Original pumps are low quality and outdated, needs to be retrofitted for efficiency. NPT fittings are leak prone and provide less flow rate, diminishing performance. An AutoVap will always outperform a rotovap!

Recommend services/upgrades:

- Replace vessel lid and adapters with larger diameter fittings for structural integrity

- Replace pump(s) with 2024 model

- Upgrade preheater to 3×36 standard size

- Flush heat exchanger and vessel shell side with CleanVap Part B

- Replacement neoprene wraps provide better insulation value and reduce burn risk from exposed hot surfaces.

Generation 2: (Buyer score: 6/10)

Generation 2 has several improvements, the connection between the evaporator and residue vessel was increased to 3 inch for structural improvement. Generation 2 also standardized the size of the preheater to 3 x 36 inch. Gen 2 still utilizes DIN style sight glasses and NPT fittings on the lids of the vessels. In addition, part way through Gen 2 production, LOK style fittings on the shell side are utilized where the heat transfer fluid circulates. Gen 2 may or may not include custom neoprene insulation wraps for the vessels and heat exchangers.

Key Points: Original pumps are recommended to be replaced with 2024 model. Look for neoprene sleeves.

Recommend services/upgrades:

- Replace pump(s) with 2024 model

- Flush heat exchanger and vessel shell side with CleanVap Part B

- Replacement neoprene wraps provide better insulation value and reduce burn risk from exposed hot surfaces.

Generation 3: (Buyer score: 8/10)

Gen 3 brings a new vessel lid design featuring all TriClamp/LOK construction and upgraded sight glasses. TruSteel switched to PulsaFeeder pumps for this model, a huge step up from the previous pumps provided. Neoprene insulation jackets come standard.

Key Points: This is the most coveted of used models on the market and offers the best performance of all the generations up to 2024.

Recommend services/upgrades:

- Flush heat exchanger and vessel shell side with CleanVap Part B

Generation 4: (Buyer score: 10/10)

Gen 4 is the current pinnacle of falling film evaporators. The condenser is no longer positioned horizontally and is on top of the condensate vessel, significantly shrinking the space required for the AutoVap15. New for Gen 4 is the introduction of LiquiFlo pumps, which have improved lifespan and more robust and inexpensive rebuild kits with in-stock lead times. Domestically sourced heat exchangers with 3/8 tubes offer increased performance of up to 30 gallons/hour. The height of the machine was also reduced by 8 inches to fit labs that are tight on ceiling height.

Key Points: It’s unlikely this model will be available used, but if you’re looking for latest and greatest for your facility, this is it!

AutoVap30

The AV30, introduced in 2018, revolutionized automated solvent recovery. We took the core concept behind the AV15, removed the collection vessels, and replaced them with pumps for continuous discharge, shrinking the footprint to fit under an 8-foot ceiling and boasting the ability to be wheeled through a standard 36 inch door with it’s 3×4 foot footprint. The AV30 features a sophisticated control system with 13 different sensors across the system for repeatability and safety features, controlled via touchscreen with programmable alarms and fail-safes. There are three distinct generations of the AutoVap 30.

Generation 1: (Buyer Score: 3/10)

Limited to 5 units, this model can be identified by it’s smaller 7 inch touchscreen. The shell side fittings are NPT style which are prone to leaks. The pumps are Oberdorfer brand which we recommend replacing. This model requires all sensors to wire back to the PLC, which almost always causes issues with used installs.

Key Points: Small touchscreen, outdated fittings, and pumps will need replacing. This is the hardest model to install and likely to be missing current TruSteel recommended ancillary equipment.

Recommend services/upgrades:

- Flush heat exchanger and vessel shell side with CleanVap Part B

- Replace pumps with 2024 models

- PLC/HMI upgrade

- Replace heater/chiller with current models

Generation 2: (Buyer Score: 5/10)

New for Gen 2 is a 12 inch touchscreen controller. Gen 2 can be identified by the Aqua Sierra serial number inside the PLC/HMI cabinet starting with BJ18XXX or BJ19XXX. This generation is still more complex to install due to all the sensors wiring back to the main PLC.

Generation 2.5: (Buyer Score: 6/10)

During the production run of Gen 2 models, we switched from NPT to LOK style fittings, and replaced the Oberdorfer pumps with PulsaFeeder models for greater longevity and reliability.

Key Points: Bigger is better, the new touch screen gives a better graphical read out and more advanced settings. Look for new LOK style fittings and PulsaFeeder pumps for greater reliability over older generations, 2024 model pumps are still recommended for longevity. Software can be buggy in these generations and typically need updating to version 2.6.

Recommend services/upgrades:

- Flush heat exchanger and vessel shell side with CleanVap Part B

- Replace pumps with 2024 models

- VPN card upgrade for remote access

- Flash Version 2.6 software

Generation 3: (Buyer Score: 8/10)

Gen 3, introduced in 2020, features significant upgrades over previous models. While Gen 1 & 2 required all 13 sensors to be wired back to the PLC controller, Gen 3 features onboard input modules built into the HMI cabinet that replaces almost all the wires with a single ethernet cable. Also standard for Gen 3 models is a VPN card that allows you and TruSteel to remotely log into your machine for startup and troubleshooting services, these features drastically reduce installation complexity and costs, while simplifying the troubleshooting process. New for this model is communication with the heater pump, chiller, and vacuum pump. The built in webserver allows you to access the machine from any internet enabled device, a cellphone, tablet, computer, etc. allowing you to start the ancillary equipment remotely on your drive to work! This feature also turns off all ancillary equipment when the emergency stop button is depressed for an extra layer of safety.

Key Points: This is the latest generation available on the used market that encompasses all the technological improvements we’ve made since the AV30’s inception.

Recommend services/upgrades:

- Flush heat exchanger and vessel shell side with CleanVap Part B

- Replace pumps with 2024 models

Generation 4: (Buyer Score: 10/10)

The new AV30 generation introduced in 2024 features upgraded LiquiFlo pumps for even better serviceability and longevity. The software has been completely revamped to allow for additional tanks and sensors to be attached to the AutoVap for greater control over your up and down-stream equipment.

Key Points: This model likely won’t be available on the used market for some time.

USED EQUIPMENT INSPECTION CHECKLIST

Heat Exchangers: Inspect for rust inside the shell side. If the equipment is disconnected and stored for a period of time with moisture inside the shell side, water vapor can rust the shell side of the heat exchangers, causing diminished performance if not serviced before commissioning, and in extreme cases cause the heat exchanger to fail, leaking heat transfer fluid into your product.

Pumps: Inspect the brand of the pump, Oberdorfer pumps are not recommended and usually require replacement in used equipment. PulsaFeeder residue pumps on the AV30 should have the coupler (green housing) inspected for leaking oil indicating a failed mechanical seal. The fan blade in the motor can be manually rotated using a screwdriver or other tool, it should spin freely with little resistance and should not make any grinding noises.

Vessels: Inspect for deformation in vessels, if exposed to high shell side pressures the internal wall of the vessel can deform creating an implosion hazard. Vessel lids with DIN style sight glasses are recommended to be replaced.

PLC/HMI cabinets: Inspect for dirt/debris inside the cabinet. Metal shavings should not be present inside. To maintain the UL listing, holes should only be drilled in the bottom side of the cabinets, any holes drilled in the top of the cabinets will void the UL listing.

Chillers: Inspect for rust inside the heat transfer fluid lines, oil leaking from the compressors, and debris in the fan filter indicating preventative maintenance was not performed. Small dents and dings usually don’t affect performance but always consult with a refrigeration expert first.

Heaters: Inspect for rust inside the heat transfer fluid lines, frayed or burnt wires inside the cabinet, and leaks.

Vacuum Pumps: Inspect for cracked or loose fittings and discolored lines.

Manifolds: Heaters and Chillers should come with TruSteel custom manifolds to ensure proper and simple installation by your plumbers that conforms to the manufacturers recommended installation setup.

USED EQUIPMENT STARTUP RECOMMENDATIONS

Heat Exchangers and all stainless plumbing lines should be flushed with CleanVap Part A to remove any oil residues, then flushed with distilled water, and again flushed with CleanVap Part B to remove any rust or mineral deposits. Flush with distilled water before commissioning. DO NOT USE CLEANVAP ON COPPER OR BRASS FITTINGS.

Gear Pumps: Pumps should be rotated by hand before spinning motors to ensure they rotate freely and don’t make any grinding noise or have excess resistance. It is always recommended to manually disassemble pumps before commissioning. Parts can be soaked in CleanVap or ethanol for cleaning.

Heaters/Chillers: A demineralizing agent rated for copper lines should be used to flush out any mineral or rust deposits before commissioning.

Inspection Guide:

General Inspection

- Visual Inspection: Start with a thorough visual inspection of the entire unit, looking for signs of wear, corrosion, leaks, or damage to external surfaces and structural components. Pay special attention to welds and joints for integrity.

- Identification Plate: Check the identification plate for model number, serial number, manufacturing date, and capacity. This information can help verify the equipment’s specifications and ensure compatibility with your needs.

- Documentation: Request all available documentation, including the original manufacturer’s manual, maintenance records, and any repair logs. This information can provide insights into the unit’s history and maintenance practices.

Heat Exchanger Inspection

- External Inspection: Examine the heat exchanger for signs of leaks, particularly at the connections and seals. Look for any discoloration or deposits that might indicate a glycol leak or previous repair attempts.

- Internal Inspection (if possible): If the unit can be safely opened, inspect the internal surfaces for corrosion, scaling, or fouling, which could affect heat transfer efficiency and fluid flow.

- Glycol Quality: Check the condition of the glycol-based heat transfer fluid if a sample is available. The fluid should be clear and free of contaminants. Dark, cloudy, or odorous fluid may indicate degradation or contamination, which can compromise performance and may require replacement.

- Pressure Testing: If feasible, conduct a pressure test on the heat exchanger to ensure integrity and the absence of leaks. This test should be performed in accordance with the manufacturer’s guidelines or industry standards.

Mechanical and Electrical Components

- Pumps: Inspect pumps for wear and operational integrity. Check seals and bearings for leaks or noises that might indicate impending failure.

- Electrical Components: Examine all electrical connections, motors, and control panels for signs of wear, corrosion, or damage. Ensure that all components are properly rated for the operational requirements of the unit.

- Sensors and Controls: Verify that all sensors, gauges, and control systems are operational and calibrated. These components are crucial for precise temperature control and overall system performance.

For any questions fill out a form below or call 530.802.0420