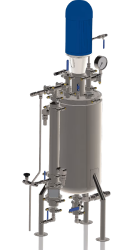

R Series

Multipurpose Reactors

In 2018 we introduced the DR-10, the first high volume reactor designed specifically for heated vacuum decarboxylation. Since then, our reactors have been used in many different industries and can be tailored to fit your exact needs and processes, with a large range of vessels available to start with or customize, we can handle any challenging process! Based on our flagship model, the DR-10, the R-Series of reactors is the most advanced modular reactor platform out there. Start with our standardized vessels and add condensers, heaters, mixers, vacuum pumps, inert or reaction gas ports, automation, and more! No challenge is too small or too big for TruSteel!

Come back soon for our exciting launch of the all-new R Series!

looking for custom reactors?

Our engineers can build the right solution for you.

Customizable Reactors

Features

Build the ultimate reactor from our customizable components, don’t see what you’re looking for? Just ask!

Chiller

With a wide range of capacities and temperature ranges to choose from, we can pair the right chiller that best fits your requirements and growth plans, when paired with an AutoVap, reactors can potentially piggyback off the AV’s chilling system

Condenser

Condensers cool vapors and return them back to their liquid state for reuse or disposal. Reflux condensers return volatiles back to the process via gravity, while traditional condensers are positioned to remove codensate from process

Vacuum Pump

For heat sensitive applications or devolatilization, several different vacuum pump styles are available from diaphragm to rotary vane to best fit your needs

Heater

For reactions or evaporation requiring heat, jacketed vessels pair with oil or glycol heaters to drive your reaction or distillation process. Dynamic control units allow heating and cooling for ultimate control over your reaction.

Mixer

Sanitary mixers keep reactions homogenized and precisely heated or cooled when using the reactor jacket. Mixers are also great for knocking down bubbles or hot break in processes like isomerization and distillation.

Pumps

Pumps allow precise metering for adding or removing product to your reaction. Titrate acids or bases, recirculate product over catalyst beds, or transfer your product to it’s next process in a closed loop.

Engineer Reviewed

3rd party peer reviewed by the industry leader, Pressure Safety Inspectors. Certified for all 50 states, so you’re covered everywhere in the entire USA! International units available, inquire within.

Control Systems

From manual controllers to advanced PLC systems, we can tailor your reactor to fit your needs and budget, and provide a path to upgrade in the future. We love making processing easier, ask what TruSteel can do for you today!